Filum cupreum 0.05mm 2UEW/3UEW155/180 inauratum ad spiram ignitionis

Principium operationis spirae ignitionis autocineti est convertere humilem tensionem continuam in altam tensionem continuam per inversionem et rectificationem dualis tensionis, quae per primarium spirae ignitionis interdum transit. Alta tensio in secundarium spirae ignitionis inducitur (plerumque circa 20KV), quae deinde candelam spirae ignitionis ad exonerationem pro ignitione impellit. Difficile est aliquas proprietates fili smaltati conventionalis pro bobinis ignitionis autocineti moderari, quia filum ruptum saepe in processu occurrit. Consideratis requisitis specialibus spirarum ignitionis, societas nostra filum smaltatum unicum pro bobinis ignitionis autocineti designat, cum aspectu excellenti, bona soldabilitate, alta resistentia mollitionis et stabilitate in fabricatione. Utimur filo cupreo tracto, quod initialiter strato basali soldabilitate temperatura humili tegitur. Deinde filum praeterea smalto mollitioni resistente tegitur. Partes huius fili sunt polyurethanum cum resistentia temperaturae altae.

Una ex proprietatibus fili metallici smaltati (G2 H0.03-0.10) ad secundariam bobinam ignitionis autocinetorum destinati est diametrus eius tenuissima. Tenuissima tantummodo tertiam partem capillorum humanorum attingit. Praeterea, cum filum crasso smalto polyurethano classis thermalis 180C confectum sit, postulationes satis altas in processu fabricationis habet. Societas nostra experientiam copiosam et technologiam maturam et provectam in designando filo metallico smaltato ad bobinas ignitionis autocinetorum destinatas habet. Processus productionis stabilis est.

1. Augmentatio resistentiae emollitionis ut non frangatur durante dissolutione emollitionis sub condicione 260℃ * 2min.

2. Melior effectus ad soldandum, superficies ad soldandum levis et munda est sine scoria soldandi sub condicione 390℃*2S.

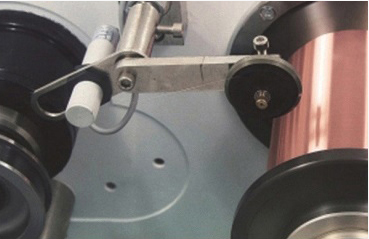

Ratio rupturae fili in processu productionis a plus quam 20% ad minus quam 1% reducitur, ut superficies sit laevior et conductivitas stabilis.

1. Insulationem compositam adhibemus: enamelum cum proprietate adglutinandi temperaturae humilis ut stratum primarium, et enamelum cum magna resistentia ad mollitiem ut stratum superius adhibetur. Ad filum compositum enamelum cum bona adglutinatione et magna resistentia ad mollitiem producendum.

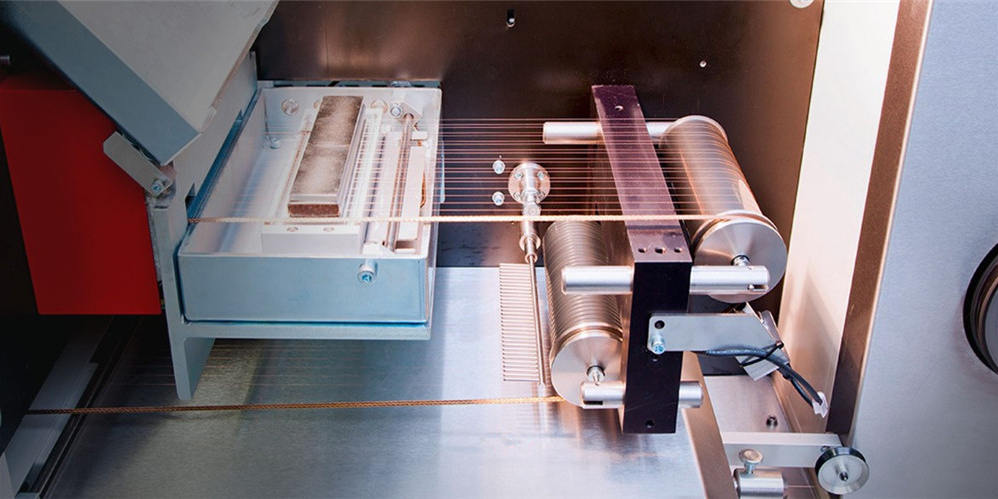

2. Melioratio technologiae productionis fili metallici smaltati: mutatio concentrationis olei tractionis durante extractione. Formae dispositae ad administrationem fabricationis superficiem laevigatam fili cuprei conducunt. Installatio instrumenti automatici ad viscositatem adaptandam et instrumenti automatici ad tensionem moderandam in processu smaltationis ratem rupturae fili minuit.

| Diameter | Tolerantia | Filum aeneum smaltatum (diametro toto) | |||||

| (mm) | (mm) | Gradus Primus | Gradus 2 | Gradus III | |||

| Minimum (mm) | Maximum (mm) | Minimum (mm) | Maximum (mm) | Minimum (mm) | Maximum (mm) | ||

| 0.030 | * | 0.033 | 0.037 | 0.038 | 0.041 | 0.042 | 0.044 |

| 0.032 | * | 0.035 | 0.039 | 0.04 | 0.043 | 0.044 | 0.047 |

| 0.034 | * | 0.037 | 0.041 | 0.042 | 0.046 | 0.047 | 0.05 |

| 0.036 | * | 0.04 | 0.044 | 0.045 | 0.049 | 0.05 | 0.053 |

| 0.038 | * | 0.042 | 0.046 | 0.047 | 0.051 | 0.052 | 0.055 |

| 0.040 | * | 0.044 | 0.049 | 0.05 | 0.054 | 0.055 | 0.058 |

| 0.043 | * | 0.047 | 0.052 | 0.053 | 0.058 | 0.059 | 0.063 |

| 0.045 | * | 0.05 | 0.055 | 0.056 | 0.061 | 0.062 | 0.066 |

| 0.048 | * | 0.053 | 0.059 | 0.06 | 0.064 | 0.065 | 0.069 |

| 0.050 | * | 0.055 | 0.06 | 0.061 | 0.066 | 0.067 | 0.072 |

| 0.053 | * | 0.058 | 0.064 | 0.065 | 0.07 | 0.071 | 0.076 |

| 0.056 | * | 0.062 | 0.067 | 0.068 | 0.074 | 0.075 | 0.079 |

| 0.060 | * | 0.066 | 0.072 | 0.073 | 0.079 | 0.08 | 0.085 |

| 0.063 | * | 0.069 | 0.076 | 0.077 | 0.083 | 0.084 | 0.088 |

| 0.067 | * | 0.074 | 0.08 | 0.081 | 0.088 | 0.089 | 0.091 |

| 0.070 | * | 0.077 | 0.083 | 0.084 | 0.09 | 0.091 | 0.096 |

| 0.071 | ±0.003 | 0.078 | 0.084 | 0.085 | 0.091 | 0.092 | 0.096 |

| 0.075 | ±0.003 | 0.082 | 0.089 | 0.09 | 0.095 | 0.096 | 0.102 |

| 0.080 | ±0.003 | 0.087 | 0.094 | 0.095 | 0.101 | 0.102 | 0.108 |

| 0.085 | ±0.003 | 0.093 | 0.1 | 0.101 | 0.107 | 0.108 | 0.114 |

| 0.090 | ±0.003 | 0.098 | 0.105 | 0.106 | 0.113 | 0.114 | 0.12 |

| 0.095 | ±0.003 | 0.103 | 0.111 | 0.112 | 0.119 | 0.12 | 0.126 |

| 0.100 | ±0.003 | 0.108 | 0.117 | 0.118 | 0.125 | 0.126 | 0.132 |

| 0.106 | ±0.003 | 0.115 | 0.123 | 0.124 | 0.132 | 0.133 | 0.14 |

| 0.110 | ±0.003 | 0.119 | 0.128 | 0.129 | 0.137 | 0.138 | 0.145 |

| 0.112 | ±0.003 | 0.121 | 0.13 | 0.131 | 0.139 | 0.14 | 0.147 |

| 0.118 | ±0.003 | 0.128 | 0.136 | 0.137 | 0.145 | 0.146 | 0.154 |

| 0.120 | ±0.003 | 0.13 | 0.138 | 0.139 | 0.148 | 0.149 | 0.157 |

| 0.125 | ±0.003 | 0.135 | 0.144 | 0.145 | 0.154 | 0.155 | 0.163 |

| 0.130 | ±0.003 | 0.141 | 0.15 | 0.151 | 0.16 | 0.161 | 0.169 |

| 0.132 | ±0.003 | 0.143 | 0.152 | 0.153 | 0.162 | 0.163 | 0.171 |

| 0.140 | ±0.003 | 0.151 | 0.16 | 0.161 | 0.171 | 0.172 | 0.181 |

| 0.150 | ±0.003 | 0.162 | 0.171 | 0.172 | 0.182 | 0.183 | 0.193 |

| 0.160 | ±0.003 | 0.172 | 0.182 | 0.183 | 0.194 | 0.195 | 0.205 |

| 0.170 | ±0.003 | 0.183 | 0.194 | 0.195 | 0.205 | 0.206 | 0.217 |

| 0.180 | ±0.003 | 0.193 | 0.204 | 0.205 | 0.217 | 0.218 | 0.229 |

| 0.190 | ±0.003 | 0.204 | 0.216 | 0.217 | 0.228 | 0.229 | 0.24 |

| 0.200 | ±0.003 | 0.214 | 0.226 | 0.227 | 0.239 | 0.24 | 0.252 |

| Diameter | Tolerantia | Resistentia ad 20°C | ||

| mm | mm | Nominalis (ohm/m) | Min (ohm/m) | Maximum (ohm/m) |

| 0.030 | * | 24.18 | 21.76 | 26.6 |

| 0.032 | * | 21.25 | 19.13 | 23.38 |

| 0.034 | * | 18.83 | 17.13 | 20.52 |

| 0.036 | * | 16.79 | 15.28 | 18.31 |

| 0.038 | * | 15.07 | 13.72 | 16.43 |

| 0.040 | * | 13.6 | 12.38 | 14.83 |

| 0.043 | * | 11.77 | 10.71 | 12.83 |

| 0.045 | * | 10.75 | 9.781 | 11.72 |

| 0.048 | * | 9.447 | 8.596 | 10.3 |

| 0.050 | * | 8.706 | 7.922 | 9.489 |

| 0.053 | * | 7.748 | 7.051 | 8.446 |

| 0.056 | * | 6.94 | 6.316 | 7.565 |

| 0.060 | * | 6.046 | 5.502 | 6.59 |

| 0.063 | * | 5.484 | 4.99 | 5.977 |

| 0.067 | * | 4.848 | 4.412 | 5.285 |

| 0.070 | * | 4.442 | 4.042 | 4.842 |

| 0.071 | ±0.003 | 4.318 | 3.929 | 4.706 |

| 0.075 | ±0.003 | 3.869 | 3.547 | 4.235 |

| 0.080 | ±0.003 | 3.401 | 3.133 | 3.703 |

| 0.085 | ±0.003 | 3.012 | 2.787 | 3.265 |

| 0.090 | ±0.003 | 2.687 | 2.495 | 2.9 |

| 0.095 | ±0.003 | 2.412 | 2.247 | 2.594 |

| 0.100 | ±0.003 | 2.176 | 2.034 | 2.333 |

| 0.106 | ±0.003 | 1.937 | 1.816 | 2.069 |

| 0.110 | ±0.003 | 1.799 | 1.69 | 1.917 |

| 0.112 | ±0.003 | 1.735 | 1.632 | 1.848 |

| 0.118 | ±0.003 | 1.563 | 1.474 | 1.66 |

| 0.120 | ±0.003 | 1.511 | 1.426 | 1.604 |

| 0.125 | ±0.003 | 1.393 | 1.317 | 1.475 |

| 0.130 | ±0.003 | 1.288 | 1.22 | 1.361 |

| 0.132 | ±0.003 | 1.249 | 1.184 | 1.319 |

| 0.140 | ±0.003 | 1.11 | 1.055 | 1.17 |

| 0.150 | ±0.003 | 0.9673 | 0.9219 | 1.0159 |

| 0.160 | ±0.003 | 0.8502 | 0.8122 | 0.8906 |

| 0.170 | ±0.003 | 0.7531 | 0.7211 | 0.7871 |

| 0.180 | ±0.003 | 0.6718 | 0.6444 | 0.7007 |

| 0.190 | ±0.003 | 0.6029 | 0.5794 | 0.6278 |

| 0.200 | ±0.003 | 0.5441 | 0.5237 | 0.5657 |

Transformator

Motor

Bobina ignitionis

Coil Vocalis

Electrica

Relay

Clientibus Curae, Innovatio Plus Valoris Affert

RUIYUAN est praebitor solutionum, quod nos requirit ut simus peritiores in filis, materiis insulationis et applicationibus vestris.

Ruiyuan, una cum progressibus in filo aeneo smaltato, hereditate innovationis fruita, societas nostra crevit per firmam fidem integritatis, servitii, et promptitudinem erga clientes nostros.

Crescere pergere speramus, qualitate, innovatione, et servitio fundatis.

Tempus traditionis medium dies VII-X.

Clientes Europaei et Americani Septentrionalis 90%, velut PTR, ELSIT, STS, etc.

Ratio emptionis 95%

Satisfactio 99.3%. Venditor Classis A a cliente Germanico comprobatus.